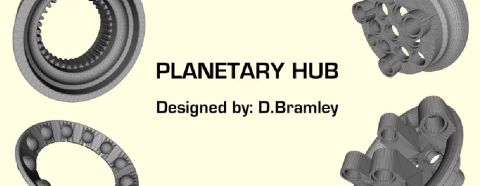

(Written by Duncan Bramley)

Having played extensively with LEGO Technic as a youth (I still have the original #853 LEGO Technic Expert Builder Car Chassis set from 1977), I now find myself playing with LEGO Technic with my son. I am a vehicle design engineer by trade, and this – combined with the time spent playing with LEGO Technic – resulted in an idea for a new LEGO Technic compatible part. After this idea had knocked around in my mind for some time and refused to go away, I decided to design in properly using 3D CAD and present it to the LEGO Group to see what they thought…

My ultimate aim is to add a set of parts to LEGO Technic that allow realistic functional models that work and behave in an authentic way. I love building things in LEGO Technic with my son that demonstrate real life engineering principles. This way he can learn through play and fun. The proposed LEGO Technic elements produce a planetary hub that is close in design to real world parts. This is why I even included rolling element bearings. Please watch the video below for a demonstration.

I hope the video gave you a good idea on how these new parts would work, and their potential. If you would like more technical details, here are some of the key features of these new LEGO Technic components:

- Planetary gear train built into a standard 56×34 rim – the gear train provides a 3:1 speed reduction and a corresponding 1:3 increase in torque. The output torque is generated at the internal gear and transmitted directly to the rim and from there to the tire or track, therefore it does not pass through any axles.

- Integrated 14 tooth track drive sprocket – increases potential applications, the rim flanges provide lateral support on the underside of the track segment plates. The sprocket is hidden when a tire is fitted.

- 4-point universal mount – this is designed to accommodate: rigid axle, rigid axle with steering, suspension or suspension with steering set-ups, all utilizing standard components. The pivot point is positioned to allow the use of either a one part universal joint or a 2-part Cardan joint.

- Rolling element bearings – provide authenticity, tight rim location with little free play and also give low rolling resistance.

I sent the above video to the LEGO Group to consider producing these new elements, but so far have had no success in convincing them. Unfortunately the project cannot be submitted through LEGO Ideas, because new part designs are specifically excluded. So I thought to reach out to the LEGO fan community for help. I’m thinking that if I can get at least 10,000 views on this video (which is the threshold for votes on LEGO Ideas for LEGO to review the project), LEGO would likely take it more seriously.

What do you think? Do you believe these new LEGO Technic parts would be a good idea? If so, please help by sharing my video with your friends through social-media, forums, blogs, and whatever other ways you can think of. Also, if you have any questions, comments, constructive criticism about the project, feel free to share in the comment section below. I will stop by to respond to them. And thank you for your support! 🙂

And you might also like to check out the following related posts:

Looks impressive, but maybe a bit too complex for LEGO? Would you talk about how would this improve the functionality of Technic models? Not all of us are engineers.

Hi jabber-baby-wocky, Thanks for your input, I hope the following comments help.

In terms of complexity, the rolling element bearings would certainly be something new to LEGO Technic, but I am keen to add to the educational value of Technic by demonstrating real world solutions. As noted in the main text, I am a strong believer in the power of learning through play and authentic parts are important in this regard.

The planetary hub packs a lot of functionality into a small space, which would allow compact but fully functional models to be built. LEGO already provide a number of elements that do this, for example the universal joint (design # 4525904) or differential (design # 4525184). Parts such as these could be constructed from “standard” Technic parts, but would then be too large to integrate into models.

The hub also generates the ultimate driving torque (twisting force) for the wheel, directly in the wheel. This torque is not transmitted via any axles – the input axle turns 3 times faster than the wheel and with 1/3 of the torque. As Technic wheels have got ever bigger, I feel that the standard axles are becoming a bit overwhelmed, you may have noticed the amount of wind-up you can get due to the axles twisting along their length under load.

Finally the hub allows a strong stable connection to be made between the hub and the model’s chassis. While the pair of bearings provide precise smooth rotation of the wheel on the hub, since there would be little free play (wobble).

I like that. The assembled parts can be used for many different things, but Lego might not like how single purpose the individual parts are. I don’t know that much about technic, but I have learned enough from my engineering classes to see the amazing potential of that design. Good work creating that.

Yes, the parts are designed as a dedicated set that fit together to produce a functional assembly. This assembly can then be built into many different models. The assembly could be regarded as a single component that replaces a standard wheel rim.

I do not think that the individual parts are useful on their own…but there are some very creative people out there!

LEGO do produce some parts that only really function as a set, the front wheel suspension & steering on the 24 Hours Race Car (set 42039) comes to mind.

Very interesting design. I suggest you produce some prototypes using 3D printing to further test the concepts, particularly regarding mechanical constraints and issues.

Then if successful you may consider approaching an established vendors already proposing Lego-compatible accessories for mass production.

I have started making some progress in the 3D printing direction, I will be posting some more videos soon.

I think you are right that 3D printing is only really suitable for prototype parts at present, the materials used on the high resolution printers are just not tough enough for functional parts. If someone from StrataSys or 3D Systems is reading this, I am quite happy for you to prove me wrong 🙂 !

The moulds needed to produce these parts in injection moulded ABS will be very expensive. Outside of TLG, I suspect that the business case would be tricky.

I think this is a great concept and would support it. I would add though that 10K views may not be enough to convince LEGO to make it. On Ideas people cast votes, so it is more than just views. It is the number of people who actually liked the idea, not just looked at the page. If you get a 100K views and favorable comments, I think that would get their attention.

I agree, if only I could put it on LEGO Ideas.

That is a really neat design; I like it, and new parts always get me excited. Narrator_Bob has a good point about the singular uses of the parts, but because LEGO has many pieces like that (BURPs come to mind), I think the main reason LEGO isn’t interested in this is because they don’t need it: they’ve made a number of sets with steering and suspension on all wheels during the past few years using standard wheels. Another problem might be that the whole setup is too many parts. But I still think it’s a brilliant idea, though, and I applaud you for coming up with it. 🙂

Wow, this is on par with the best of what Technic has to offer. Bravo! This would make great teaching lab material.

Given that LEGO isn’t interested, perhaps investigate pairing with someone who makes custom LEGO parts? Or contact national embassadors (i.e. Sariel) and widen your support base.

Looks like a lot of parts to patent. Also there may be some patent issues with that already.