To celebrate the 40th anniversary of the minifigure, LEGO collected and sent out a big bundle of assets to LEGO fan sites to enjoy and share with their communities. The original date when the first minifig patent was registered in Denmark was August 29th 1977, however, the first minifigures weren’t launched until 1978. Last time, we looked at the timeline of the development of the LEGO minifigure (see: The Story of the LEGO Minifigure – Part 1), and today, we will take a look at the minifig moulds. 🙂

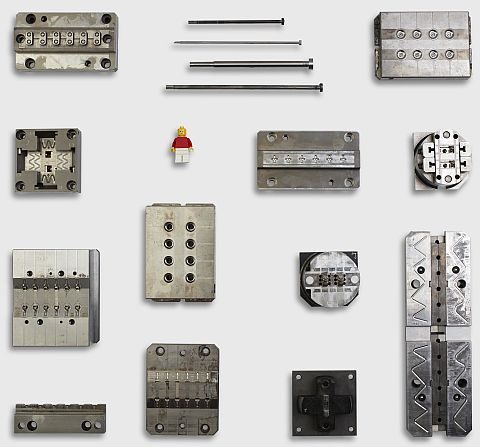

The standard LEGO minifigure is assembled from nine pieces; head, torso, two arms, two hands, hips piece, and two legs. To make the pieces, eight different moulds are used. Two sets of these moulds are the same in design but reversed to mould the right and left minifigure arms and legs. As we discussed in the first part of this series, the precision that goes into these moulds is exceptional, and because the original moulds are almost identical to the ones LEGO uses today, minifigures from 1978 can be mixed and matched with the more modern characters from today. A couple of things that changed, however, is the number of elements each mould can produce and the speed of production. For example, the minifigure head mould construction has improved from an initial eight elements per 9.8 seconds to 128 elements per 14.7 seconds today. Below, I’m including again the footage from the LEGO factory in Kladno, Czech Republic, just because it’s so awesome.

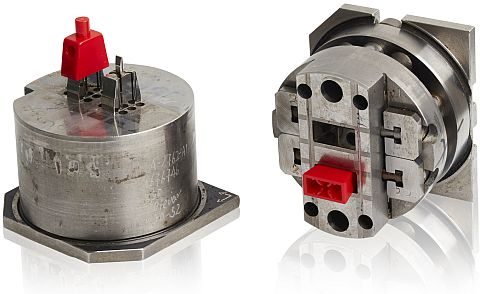

In the video above, you can clearly see how the moulds are used for manufacturing the different body parts of the standard LEGO minifig, and below are close-ups of the moulds. The first image shows the two sides of the minifig head mould.

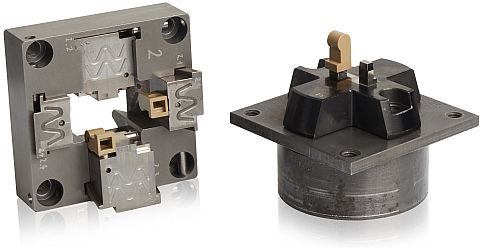

The second image shows the two sides of the minifig torso mould. Notice all those intricate small pieces inside the torso, which helps with rigidity and keeping the studs of the hips piece in place.

The left and right arms and the hands are made in separate moulds, and attached to the torso later in the manufacturing process as seen in the video above. I found it especially interesting how the machines clipped those tiny hands in place. So impressive!

The leg assembly is made up of three pieces; the right leg, the left leg, and the hips piece. The left and right legs are produced in the same moulding assembly, and the hips come from a separate mould. These are also later assembled by machines.

It’s great to get such an intimate glimpse into how LEGO minifigs are made! What do you think? How do you like the mould images? Did you notice any interesting details during the manufacturing process? Feel free to share your thoughts and discuss in the comment section below! 😉

And you might also like to check out the following related posts:

Machines for mass-production have always fascinated me and of course LEGO producing ones are even more intriguing! Super cool to see the processes, amazing to think how much goes into one minifigure!

This is fascinating! Even though Lego it’s just a toy, it’s remarkable how much engineering, planning, logistics, and everything else goes into making it.

I find it impressive and inspiring that even though Lego is a building toy, they put in that much care and effort into manufacturing such a quality product that even the name brings respect.

Very true.

These molds are a work of art! Do we know who makes them? Does Lego make them themselves? Or are them made by some other company?

“they” not “them”. sorry.

In the following discussion on Brickset, someone mentions that the machines are likely made by an Austrian company named Engel, as they make the vast majority of injection moulding machines. The moulds themselves, however, are made by someone else: https://brickset.com/article/38189/the-making-of-a-minifig

When you visit the LEGO factory, do you have a chance to see these machines up close? I would love to check them out.

There is a factory tour, but I’m not sure how close you can get to the moulding machines. I’m sure safety is their #1 concern, so they will only allow visitors to view the operation from a safe distance.

That was so impressive to watch. It happens so fast ( well it has to be to keep up with the demand) I had to watch it again. This might also explain why some times the prints are a little off sometimes ( jangbricks points that out from time to time). And also you can sometimes see the stress in the plastic where the legs attached to the waist piece . It used to happen to me that the mini figures leg would be loose or fall right off even after it being brand new ( out of the box), but , I complained enough times that I think they fix the problem. In fact Lego customer service would send me replacements but , I told them that it doesn’t fix the problem and to tell let the Lego company know wants happening to the mini figures. Because it was happening a lot to me . I guess I’m just that lucky. Lol.this happened when I just started getting into Lego ( about 11 and a half years ago).

Yes, it’s always a great idea to report any issues, even if you don’t want replacements. They take those reports very seriously, and can help them track down where the problem originated. I would mention though that while most LEGO sets in the US are made in the factory in Mexico, replacement parts usually come directly from Denmark. They often don’t have the problems that pieces made in Mexico (or China, or other places) have.

I heard that lego buries the moulds they retire. Is that true? Why don’t they just put them in a museum or something?

I’m not sure if they still do it, but they certainly did it in the past. Your idea does make sense. Perhaps retired moulds could be displayed at the LEGO House. 🙂

I guess a few of the moulds could be put in a museum, but there likely are too many of them to keep every one that gets retired.

I guess they generally could be molten into new moulds, however.

Yeah, it’s possible that they retool the moulds, but I’m really not sure. The whole thing is like magic as far as I’m concerned! 😀

Those hands are so tiny! It’s amazing what machines can do these days. The kids love the video and now want to visit the factory. Only if it wasn’t so far…. sigh..

I do still ask ( from time to time) for replacement parts . But, I’m glad things have gotten better and I haven’t had any problems since . Knock on wood. Lol. It also let’s us Lego fans know that Lego does stand behind there products and there customers.

Yeah, they take quality control seriously. It really is nice to see.