As Star Wars Celebration kicks off this weekend in London, The LEGO Group has announced two new diorama building sets featuring iconic scenes from Star Wars: Return of the Jedi for LEGO Star Wars fans, to mark 40 years since the film’s original release.

LEGO Star Wars fans will be able to re-build the iconic final duel between Luke Skywalker and Darth Vader in the Emperor’s Throne Room, or descend to the forest floor and recreate the action-packed Endor Speeder Chase, with each set packed with recognizable characters and the chance to re-create memorable moments.

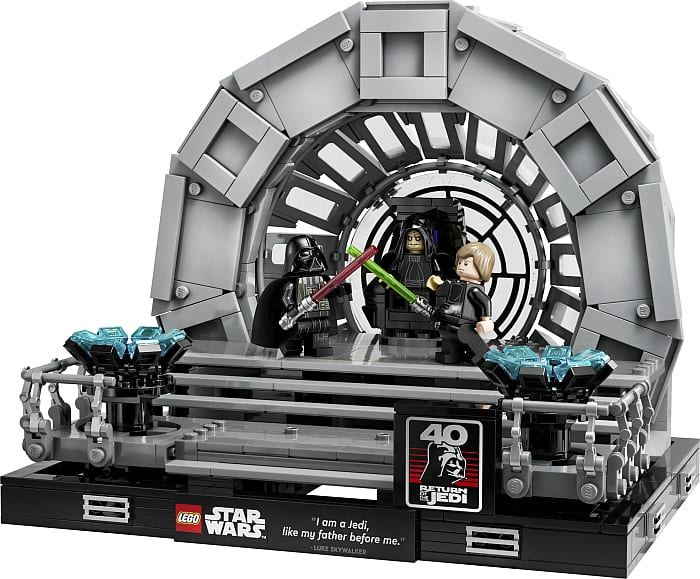

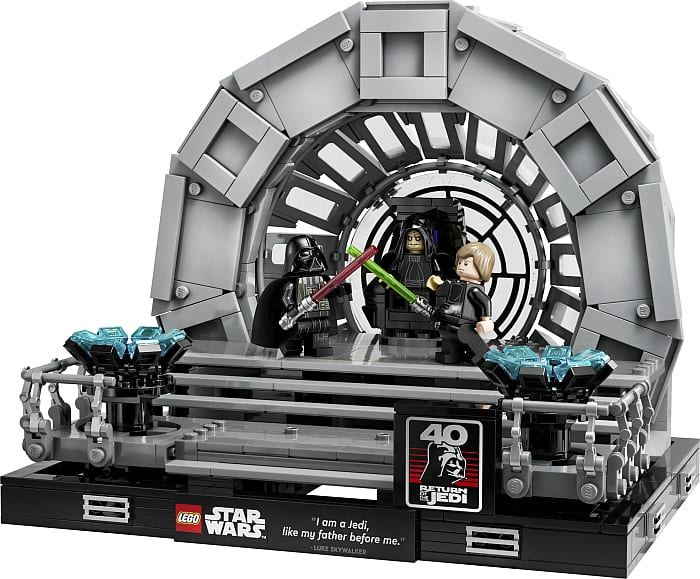

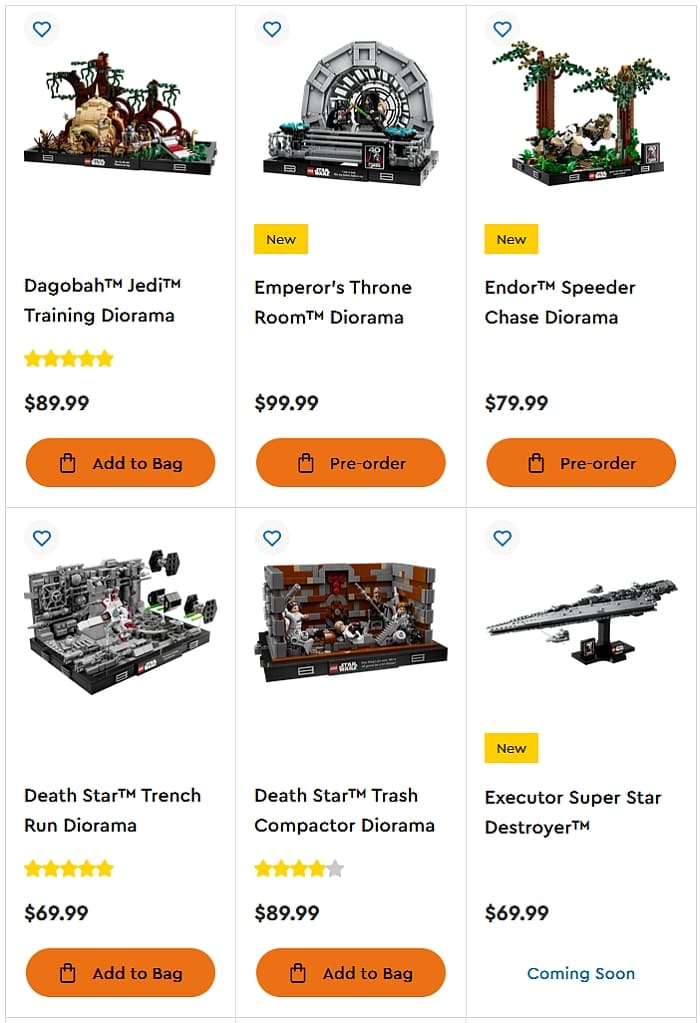

The 807-piece #75352 LEGO Star Wars Emperor’s Throne Room Diorama building set is an accurate LEGO brick representation of Emperor Palpatine’s Throne Room on the re-built Death Star featured in Return of the Jedi, including its instantly recognizable window, the Emperor’s chair, and many other details.

Also included in the set are three minifigures featuring the characters Luke Skywalker, Darth Vader (both with their lightsabers), and Emperor Palpatine, whose lightsaber and bolts of Sith lightning are hidden on the underside of the model. The minifigures can be placed in different positions on the diorama to replicate different moments from the scene. Prices are as follows: €99.99 / $99.99 / £89.99 / 159.99 AUD /42990.0 HUF /2499.9 TRY/129.99 CAD. Available at the LEGO Star Wars section of the Online LEGO Shop.

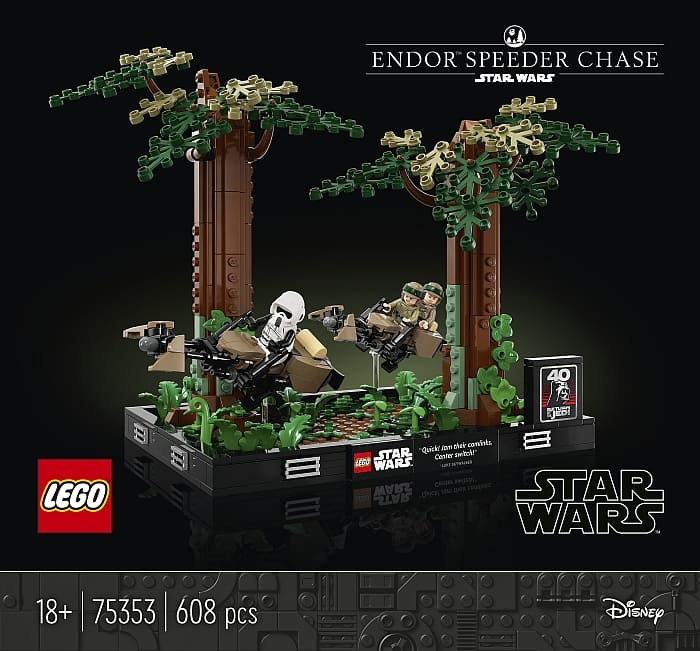

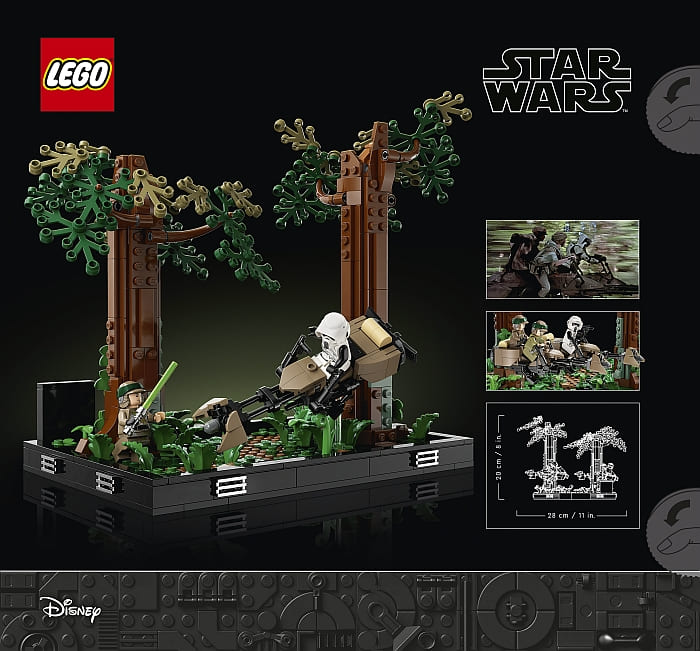

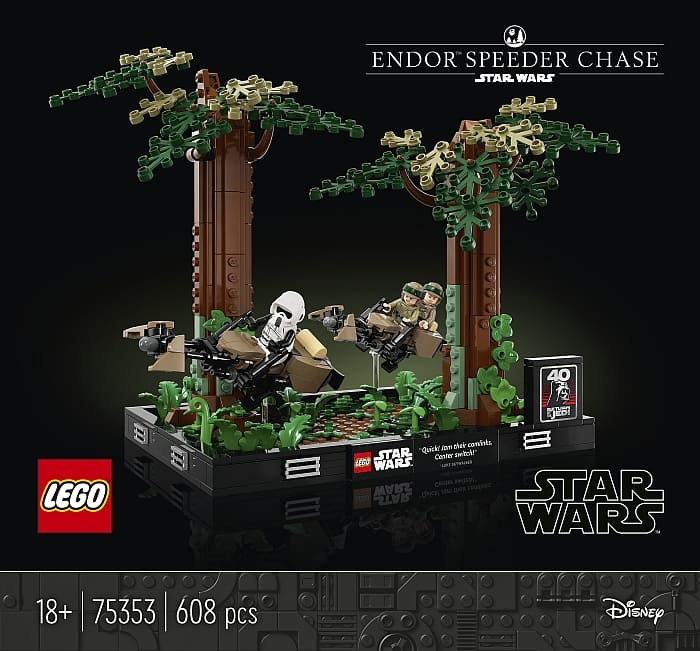

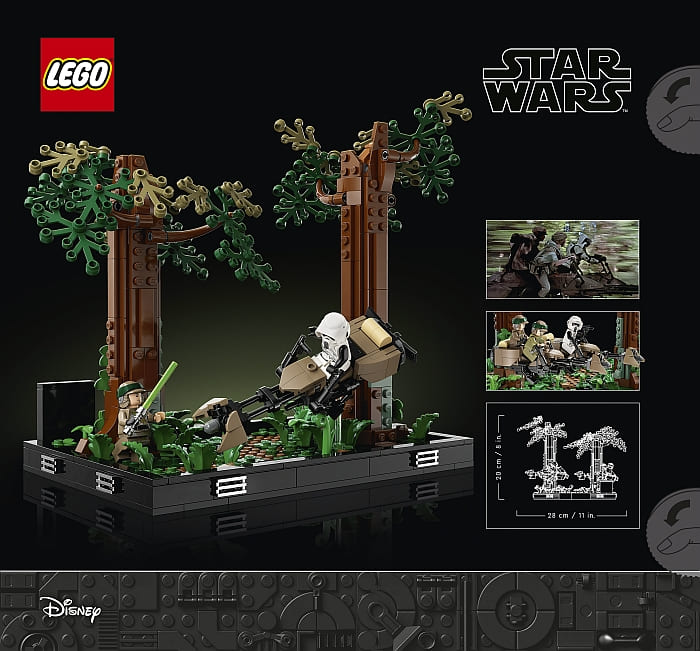

For fans journeying to Endor, the 608-piece #75353 LEGO Star Wars Endor Speeder Chase Diorama brings to life the high-speed action amongst the lush forest floor, with Luke Skywalker racing on a speeder bike between the trees.

The set includes three minifigures based on the characters, Luke Skywalker, Princess Leia, and a Scout Trooper, and sees builders recreate the two speeder bikes and forest environment, from the greenery on the ground to Endor’s tall treetops. Prices are as follows: €79.99 / $79.99 / £69.99/34990.0 HUF/129.99 AUD/1999.9 TRY/99.99 CAD. Available at the LEGO Star Wars section of the Online LEGO Shop.

These two new diorama building sets are highly detailed and each features a printed display plaque with a movie quote, making perfect display pieces for fans to add to their LEGO Star Wars collection and mark four decades since the original trilogy in the Skywalker Saga concluded.

“It’s hard to over-state the impact that Return of the Jedi has had on popular culture since its release 40 years ago, and it was a real pleasure as a fan to help create these new dioramas that celebrate some of the film’s most iconic moments,” said Jens Kronvold Frederiksen, Design Lead for LEGO Star Wars. “Whether you were in the cinema for Return of the Jedi’s original release or came to discover it later, these two dioramas allow builders to recreate and display their own slice of cinematic history – and revealing them to fans, at the same time as many are enjoying Star Wars Celebration, is the perfect way to unveil them.”

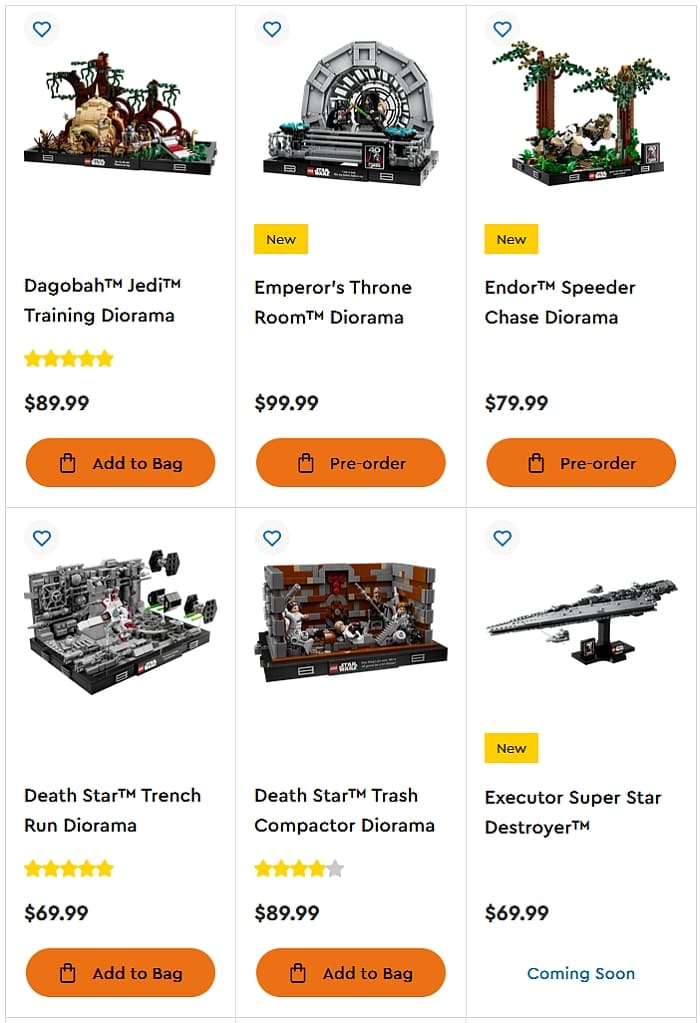

The LEGO Star Wars portfolio introduced diorama building sets of iconic franchise moments in 2022, with three scenes including the #75329 LEGO Star Wars Death Star Trench Run Diorama, the #75330 LEGO Star Wars Dagobah Jedi Training Diorama, and the #75339 LEGO Star Wars Death Star Trash Compactor Diorama.

Both sets are available to pre-order from today, April 7th, and available to purchase from May 1st from the LEGO Star Wars section of the Online LEGO Shop.

What do you think? How do you like the LEGO Star Wars Diorama sets? Feel free to share your thoughts and discuss in the comment section below!

And you might also like to check out the following related posts: